Understanding the HM88 Series Manifold

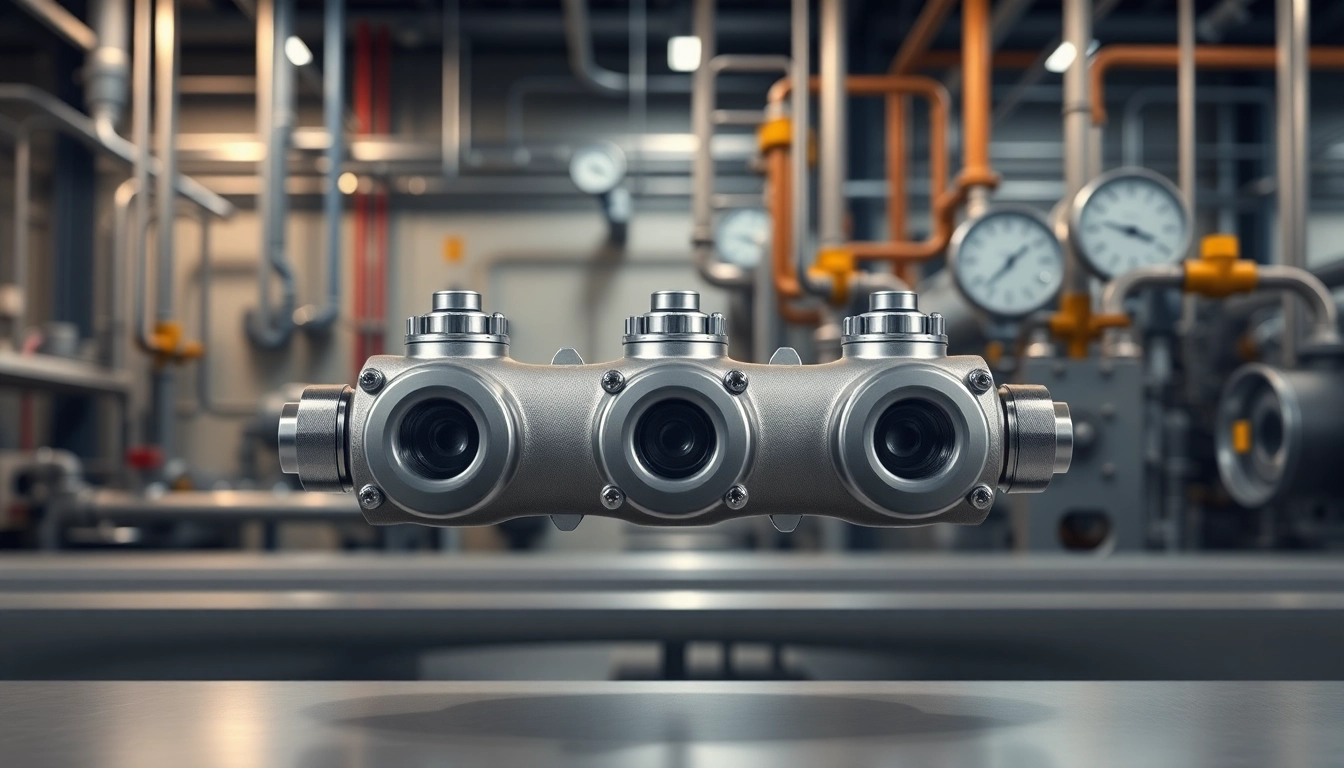

The HM88 Series Manifold represents a critical innovation in the realm of fluid management systems, designed to streamline processes in various industrial applications. This manifold system excels in providing reliable pressure management and is built for durability under rigorous operational conditions. When exploring options, hm88 provides comprehensive insights into the utility and design of the HM88 series, offering robust solutions for pressure transmitter integration.

What is the HM88 Series?

The HM88 Series is specifically engineered as a three-valve direct mount manifold, facilitating the close-coupled installation of pressure transmitters to an orifice flange. Designed by leading industry manufacturers, the HM88 series stands out for its efficient design and adaptable applications across diverse sectors including oil and gas, chemical processing, and water treatment. This manifold employs a robust construction to ensure it can withstand high pressures and harsh environments.

Key Features and Specifications

- Material Construction: Typically made from stainless steel for enhanced corrosion resistance.

- Pressure Ratings: Can handle high pressures, often rated up to 6000 psi or above.

- Temperature Range: Functional in a wide temperature spectrum, usually from -50°F to 300°F.

- Compact Design: Facilitates close-coupled mounting options to save space without compromising performance.

Applications in Industry

The HM88 Series is versatile, being suitable for a variety of applications, including but not limited to:

- Oil and Gas Exploration: For accurate pressure measurements in drilling operations.

- Chemical Processing: To maintain precise flow control in hazardous environments.

- Water Treatment: Used for monitoring and controlling pressure in water distribution systems.

Benefits of the HM88 Design

Why Choose HM88? Key Advantages

Choosing the HM88 Series manifold provides several significant advantages, including enhanced reliability due to its robust design and ease of integration with existing systems. Its compact size makes it an excellent choice when space is at a premium. Additionally, the reliable construction ensures minimal downtime due to failure, which is critical in industries where uptime is paramount.

Efficiency in Fluid Management

The HM88 manifold achieves highly efficient fluid management by minimizing pressure drops and allowing for precise control over flow dynamics. This efficiency results in lower operational costs, as less energy is required to maintain system pressures. Furthermore, the direct mount design reduces the number of potential leak points, thus enhancing system integrity and safety.

Compatibility with Industry Standards

Manufactured to meet various industry standards, including ISO and ANSI specifications, the HM88 Series ensures that it is compliant with most operating environments. This adherence to standardization means that users can integrate these manifolds into their systems with confidence, ensuring compatibility and safety.

Installation and Maintenance Tips

Best Practices for Installation

Proper installation of the HM88 manifold is crucial for optimal performance. Follow these guidelines:

- Ensure all fittings are clean and free from debris before assembly.

- Use the recommended torque settings to avoid over-tightening.

- Verify that the system is depressurized before installation to ensure safety.

Routine Maintenance Guidelines

Maintaining the HM88 Series is essential for prolonged longevity. Regular checks should include:

- Inspecting for signs of wear or corrosion.

- Ensuring valves operate smoothly without sticking.

- Regularly testing pressure settings to ensure they remain within designated limits.

Common Issues and Troubleshooting

Despite its robust design, issues may arise. Common problems include pressure leaks or valve malfunctions. In case of a leak, inspect the fittings and seals first, as improper installation is often the cause. For valve issues, extensive cleaning may resolve sticking problems, but replacement may be necessary if structural integrity is compromised.

Comparative Analysis with Competitors

HM88 vs. Other Manifold Series

When compared to competitor products, the HM88 Series often shows superior performance in terms of durability and operational efficiency. Competitors may offer alternative designs, but the proven resilience and efficiency of the HM88 often make it the preferred choice among industry professionals.

Market Position and User Verdicts

The HM88 holds a strong position in the marketplace due to its consistent reliability and performance. User reviews frequently cite its ease of installation and maintenance as key benefits, along with its robust construction. This favorable reputation strengthens the HM88’s position as a leading choice for manifold systems.

Case Studies: Real-World Applications

Many industries have successfully integrated the HM88 Series, demonstrating its versatility and effectiveness. For instance, in offshore oil drilling, the HM88 has been instrumental in ensuring accurate pressure monitoring, thereby preventing potential operational hazards.

Future Trends for Manifold Systems in 2025

Emerging Technologies and Innovations

As the industry moves towards increased automation and smarter systems, manifold technology is evolving. The integration of IoT (Internet of Things) technology into manifold systems is anticipated, allowing for real-time data monitoring and predictive maintenance. This innovation will likely enhance operational efficiency and safety protocols significantly.

Potential Market Shifts

The demand for high-performance manifold systems is expected to rise, particularly in emerging markets where industrialization is accelerating. Manufacturers must adapt to changing consumer expectations for sustainable and efficient products, which will shape the design and functionality of future manifold systems.

Expert Insights and Predictions

Industry experts predict that by 2025, manifold systems like the HM88 will incorporate advanced materials and design innovations, further improving their performance under extreme conditions. The move towards environmentally friendly materials is also expected to reshape the market, aligning with sustainability trends.